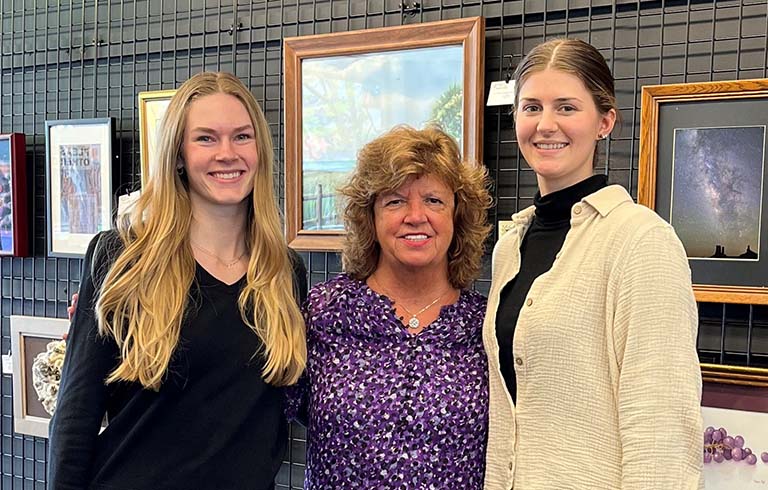

Trine students help Revive Art in Steuben County

An upcoming community art show that two Trine University marketing majors helped develop not only promotes creativity, but sustainability.

May 03, 2024

Trine placed 55th out of 107 teams that competed in the event, held April 18-20 in Wichita, Kansas.

The team was comprised of mechanical engineering majors Zach Griffith of Springport, Michigan, Ryan Harris of Warsaw, Indiana, Gavin Hettler of Coatesville, Indiana, Levi Peterson of Portland, Indiana, Hayden Rader of Arcadia, Ohio, and Bailey Zurface of Spencer, Indiana.

Developing processes

The team decided to use carbon fiber because it allowed them to reduce the weight of their aircraft while increasing stiffness. However, that meant they had to develop processes for working with the carbon fiber.

“Our plane was required to have a takeoff distance under 20 feet, so any weight we added during construction would come back to bite us in our scores, but it needed to be strong enough to support itself as well,” Peterson said.

“We taught ourselves everything we know about the best ways to manufacture carbon fiber to build this plane and have helped foster the birth of a composites research lab on campus.”

“Preparation of molds and lay-up methods can be quite challenging when fabricating aircraft parts with complex geometries,” noted Gurudutt Chandrashekar, Ph.D., assistant professor and faculty advisor. “With extensive literature research, the team devised mold-making methods that aided in building multiple planes within a short period of time.”

“We also were one of the first teams to successfully use 3D-printed components in highly loaded structures,” said Rader. “Our wing mounting was entirely 3D printed as well as our pins that allowed the wings to fold. Our tail mounts, fuse mount and front landing gear servo mount were all also 3D printed.”

The team was able to leverage work and classroom experience and training throughout the manufacturing and assembly process. However, none of them had experience with remote control systems.

“In total, it took me over a week just to learn how to program the controller for the airplane, and I know that I haven’t even scratched the surface of how complex most of these systems are,” said Peterson.

Top competition, windy conditions

Team members said flying to Wichita for the competition gave them the confidence that they deserved to compete with some of the top aerospace engineering programs in the world.

“It made me feel like all the hard work and heavy lifting throughout the year had paid off,” said Hettler.

Conditions during the competition were windy, resulting in many aircraft crashing. However, the Trine team was able to successfully complete their first mission.

“We didn’t make the takeoff requirement on the first go around, so the pilot had to swing the plane back around and make a quick landing,” said Hettler. “When doing this he landed very hard and bent the front landing gear. I ran back out there and bent it back into place and he took off again. This time the takeoff was successful, all laps were flown and the landing was successful.”

“The absolute whirlwind of this whole scenario was awesome, and it felt amazing when he landed.”

Unfortunately, the continued winds and a motor failure resulted in a crash on the second mission. While Trine finished 12 spots higher than the judges had ranked the team at the start of competition, the team was disappointed they didn’t perform better.

“We only completed two of the four missions,” said Rader. “Had we completed the other two, we would have placed in the top 25-30.”

Despite not placing as high as they would have liked, the team said the experience was unforgettable.

“I feel as if it strengthened my relationship even more with the entire group,” said Rader.

“I don’t know if I am ever going to touch model RC again, at least not immediately after this project, but I may have to revisit it in a few years when I can stomach crashing planes again,” said Peterson.